You stare at dozens of optical sorter options online. Each claims to be the "best." Your production line waits while defective products slip through manual inspection.

The truth is simple: there is no universal "best" optical sorter. The right choice depends entirely on your specific material type, detection precision requirements, processing speed needs, and budget constraints.

I have worked in manufacturing for over 30 years. I have seen companies waste millions on the wrong equipment. The key is understanding your exact needs before making any decision.

What is the Purpose of a Sorting Machine?

Your production line generates thousands of products daily. How do you ensure only perfect ones reach your customers? Manual inspection fails when volumes increase.

Sorting machines automatically classify, grade, or reject products based on preset standards. They replace human workers with consistent, high-speed quality control that never gets tired or distracted.

Modern sorting machines serve three core functions that transform manufacturing efficiency. First, they perform classification based on physical properties1 like size and weight. Second, they detect optical characteristics2 including color variations and surface defects. Third, they analyze chemical composition such as sugar content in food products.

The real value lies in replacing inconsistent human judgment with precise automation. Human inspectors suffer from fatigue after just two hours of continuous work. Their accuracy drops significantly during night shifts or overtime periods. Sorting machines maintain the same detection precision whether it is the first product or the ten-thousandth product of the day.

These machines also create detailed production records3. Every rejected item gets logged with timestamp and defect type. This data helps identify production issues before they become major problems. For example, if rejection rates4 spike at 2 PM daily, you know to check equipment calibration during that timeframe.

| Sorting Method | Detection Speed | Accuracy Rate | Cost Efficiency |

|---|---|---|---|

| Manual Inspection | 50-100 pcs/min | 85-95% | Low initial, high labor |

| Optical Sorting | 1000-10000 pcs/min | 98-99.9% | High initial, low operating |

| Combined Systems | 500-5000 pcs/min | 99.5-99.99% | Medium initial, optimal ROI |

What is the Optical Inspection System for Quality Control?

Quality control demands perfect vision that never blinks. Traditional inspection methods cannot match the precision requirements of modern manufacturing standards.

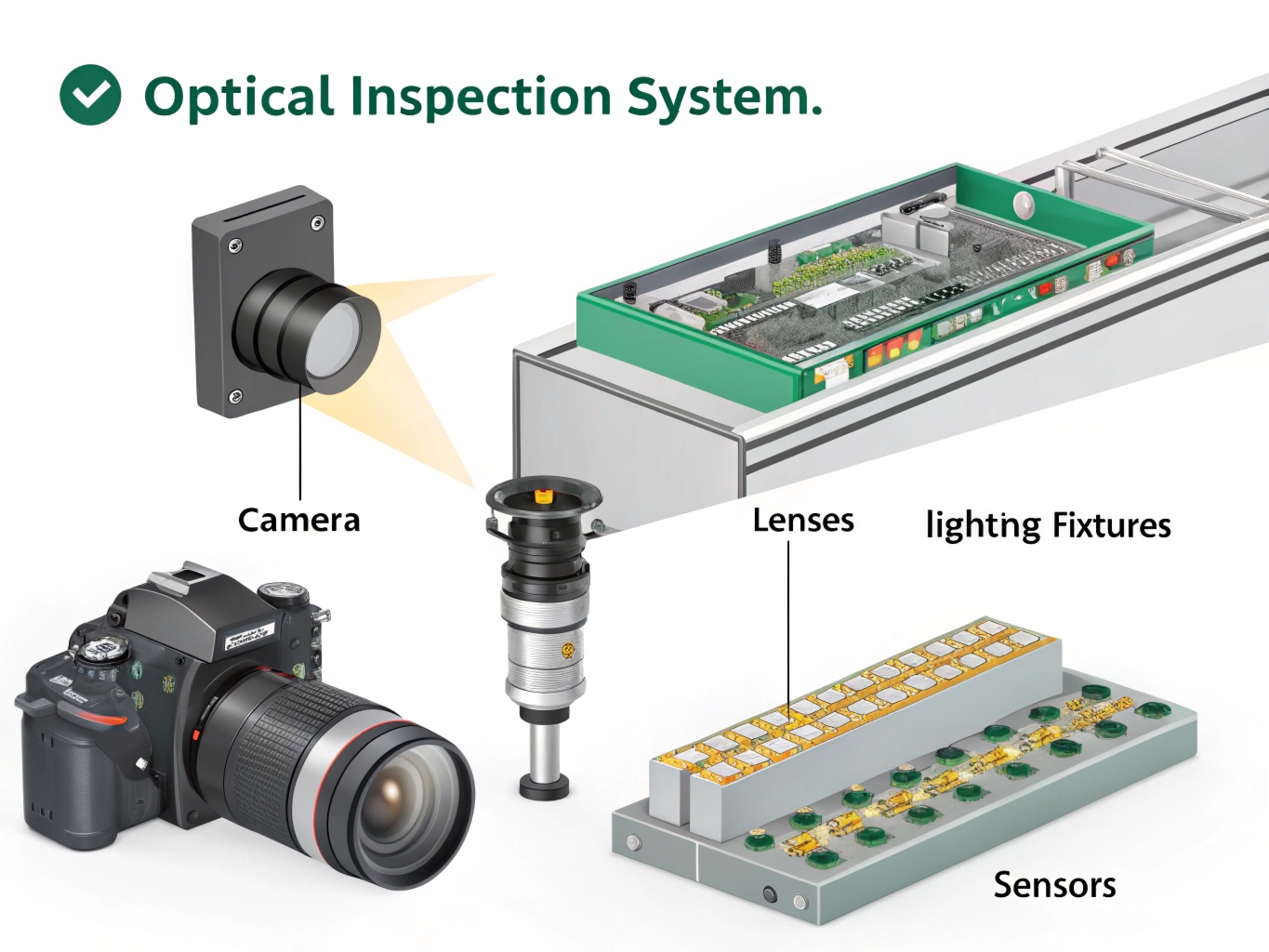

Optical inspection systems use light-based technology for non-contact product evaluation. They include both online detection systems integrated into production lines and offline precision measurement equipment for laboratory analysis.

The optical inspection ecosystem includes two distinct categories that serve different quality control needs. Online systems perform real-time monitoring during production. These include Automated Optical Inspection (AOI) systems5 and optical sorting machines6. They examine every product or perform statistical sampling as items move through the production line.

Offline precision measurement equipment handles detailed analysis in controlled laboratory environments. Confocal microscopes achieve nanometer-level resolution for three-dimensional surface measurements. They detect microscopic defects on optical components and micro-lens arrays that would be impossible to identify during high-speed production.

White light interferometers provide another layer of precision measurement. They measure surface topology and roughness with quantifiable data. This equipment supports the entire quality control process from design verification through incoming material inspection to failure analysis.

The integration of these systems creates a comprehensive quality control network. Online systems catch obvious defects during production. Offline systems provide the detailed analysis needed for process improvement and root cause investigation. Together, they ensure product quality meets the most demanding specifications.

How Does an AOI Work?

You watch a human inspector examine products under a magnifying glass. They spot some defects but miss others due to fatigue. AOI systems never get tired.

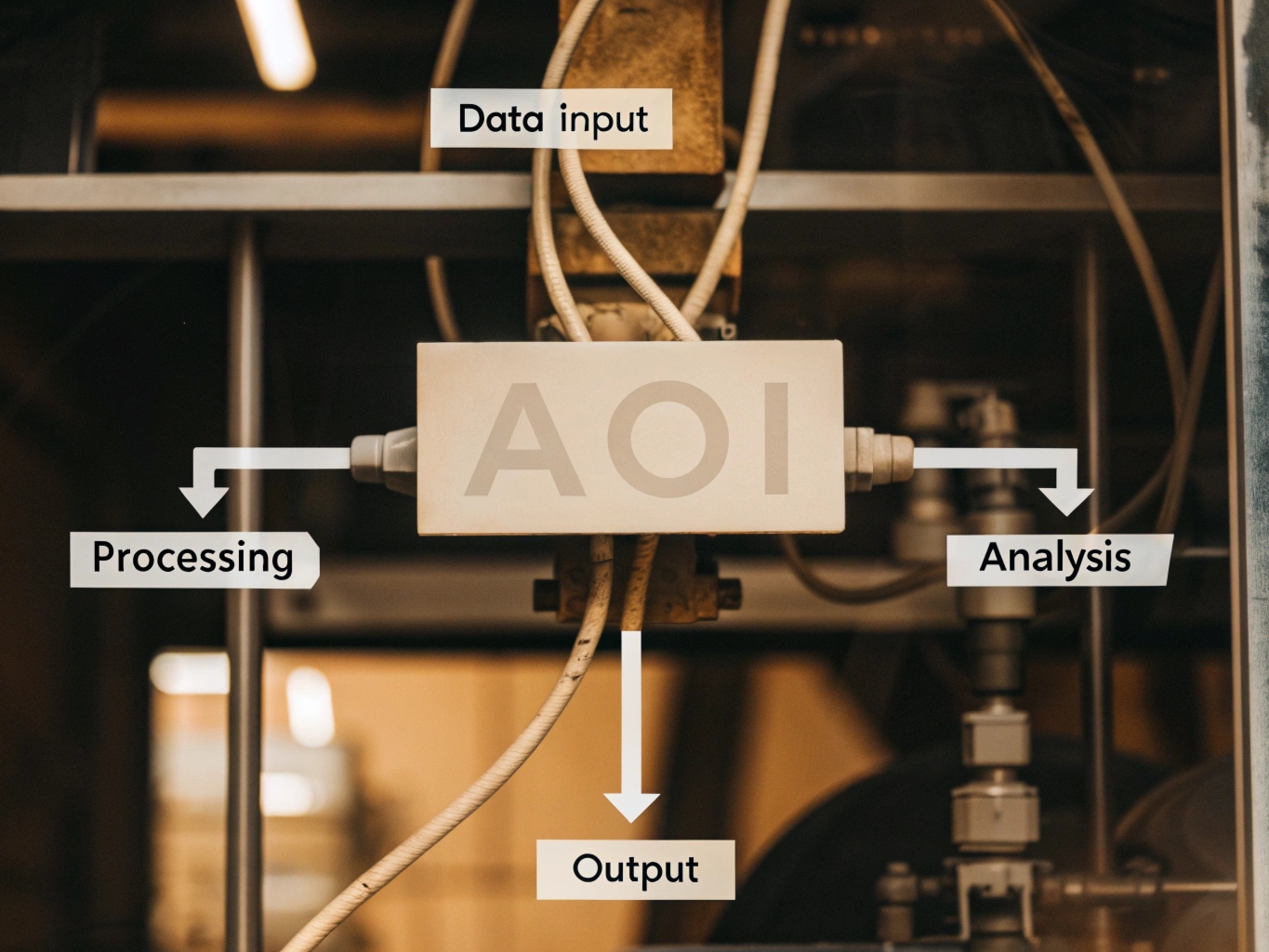

AOI mimics human vision but operates faster and more consistently. It captures high-resolution images, processes them through advanced software, compares results against quality standards, and triggers appropriate actions for defective products.

The AOI workflow consists of four critical stages that replicate and improve upon human inspection capabilities. Image acquisition7 begins with specially designed lighting systems. LED arrays provide illumination from multiple angles and colors to highlight specific product features. Industrial cameras equipped with CCD or CMOS sensors capture high-resolution images that reveal details invisible to human eyes.

Data processing transforms raw images into analyzable information. Software algorithms reduce image noise and enhance contrast to make target features more prominent. This preprocessing step is crucial because it determines the quality of subsequent analysis stages.

Image analysis represents the "brain" of the AOI system. Software extracts feature measurements and compares them against pre-established quality templates. Any deviation beyond acceptable tolerances gets flagged as a potential defect. The system uses pattern recognition and machine learning algorithms to distinguish between acceptable variations and actual quality issues.

Defect reporting completes the cycle by marking defect locations and triggering appropriate responses. The system can sound alarms, send signals to robotic arms for product removal, or activate pneumatic systems to blow defective items off the production line. All results get logged in databases for quality tracking and process improvement analysis.

| AOI Component | Function | Typical Specifications |

|---|---|---|

| LED Lighting | Feature illumination | 365nm-850nm wavelength range |

| Industrial Camera | Image capture | 1-50 megapixel resolution |

| Processing Unit | Data analysis | 0.1-10 second cycle time |

| Output System | Defect response | 99.9% reliability rating |

Why is AOI Important?

Manufacturing quality standards increase every year. Customer expectations rise while profit margins shrink. Manual inspection cannot keep pace with these demands.

AOI systems are essential for modern smart manufacturing because they improve product quality, increase production efficiency, reduce manufacturing costs, and enable data-driven quality management that was impossible with manual methods.

Quality and reliability improvements8 represent the most visible AOI benefits. These systems detect microscopic defects9 that human inspectors cannot see consistently. They identify problems that would cause field failures months after product delivery. This early detection prevents warranty claims and protects brand reputation.

Production efficiency gains multiply throughout the manufacturing process. AOI systems inspect products at speeds that match or exceed production line requirements. They eliminate inspection bottlenecks that slow down entire operations. Fast detection also enables immediate corrective actions before defective products accumulate.

Cost reduction occurs through multiple channels beyond obvious labor savings. While initial equipment investment seems high, long-term savings are substantial. AOI prevents batch-level losses caused by undetected systematic defects. It reduces rework costs and eliminates customer return expenses that damage profitability.

Data-driven management capabilities transform quality control from reactive to predictive. Every inspection result gets recorded with detailed metadata including time stamps and defect classifications. This information enables statistical process control10 and identifies trends before they become major problems. Quality managers can optimize production parameters based on actual performance data rather than guesswork.

The combination of optical sorting machines and AOI systems creates a complete quality control solution. Sorting machines provide the physical "separation of good from bad" while AOI systems deliver the intelligent "judgment of good versus bad." Advanced offline optical measurement equipment adds precision data support for process development and detailed analysis.

Conclusion

The best optical sorter depends on your specific materials, defects, and production requirements. Contact our 30-year manufacturing team for personalized analysis and testing recommendations.

-

Understanding this classification can enhance your manufacturing processes and improve efficiency. ↩

-

Exploring this topic can reveal advanced technologies that optimize quality control in production. ↩

-

Understanding the importance of production records can help improve efficiency and quality control in your operations. ↩

-

Exploring the effects of rejection rates can provide insights into optimizing production and reducing waste. ↩

-

Discover how AOI systems enhance quality control and improve production efficiency, making them essential in modern manufacturing. ↩

-

Learn about the role of optical sorting machines in ensuring product quality and efficiency in production processes. ↩

-

Understanding image acquisition is crucial for enhancing inspection processes and improving product quality. ↩

-

Exploring this link will provide insights into how quality and reliability enhancements can significantly impact production and customer satisfaction. ↩

-

This resource will explain the technology behind detecting microscopic defects, crucial for maintaining product quality and preventing failures. ↩

-

Learn about statistical process control to see how it helps in identifying trends and improving quality management. ↩

Written by

You may also be interested in:

How Does Visual Inspection Work?

Every manufacturer faces quali

What is the vision system for visual inspection?

Modern manufacturing demands p