Every manufacturer faces quality control challenges. Without proper inspection, defective products can slip through, damaging reputation and increasing costs. Visual inspection offers a reliable solution.

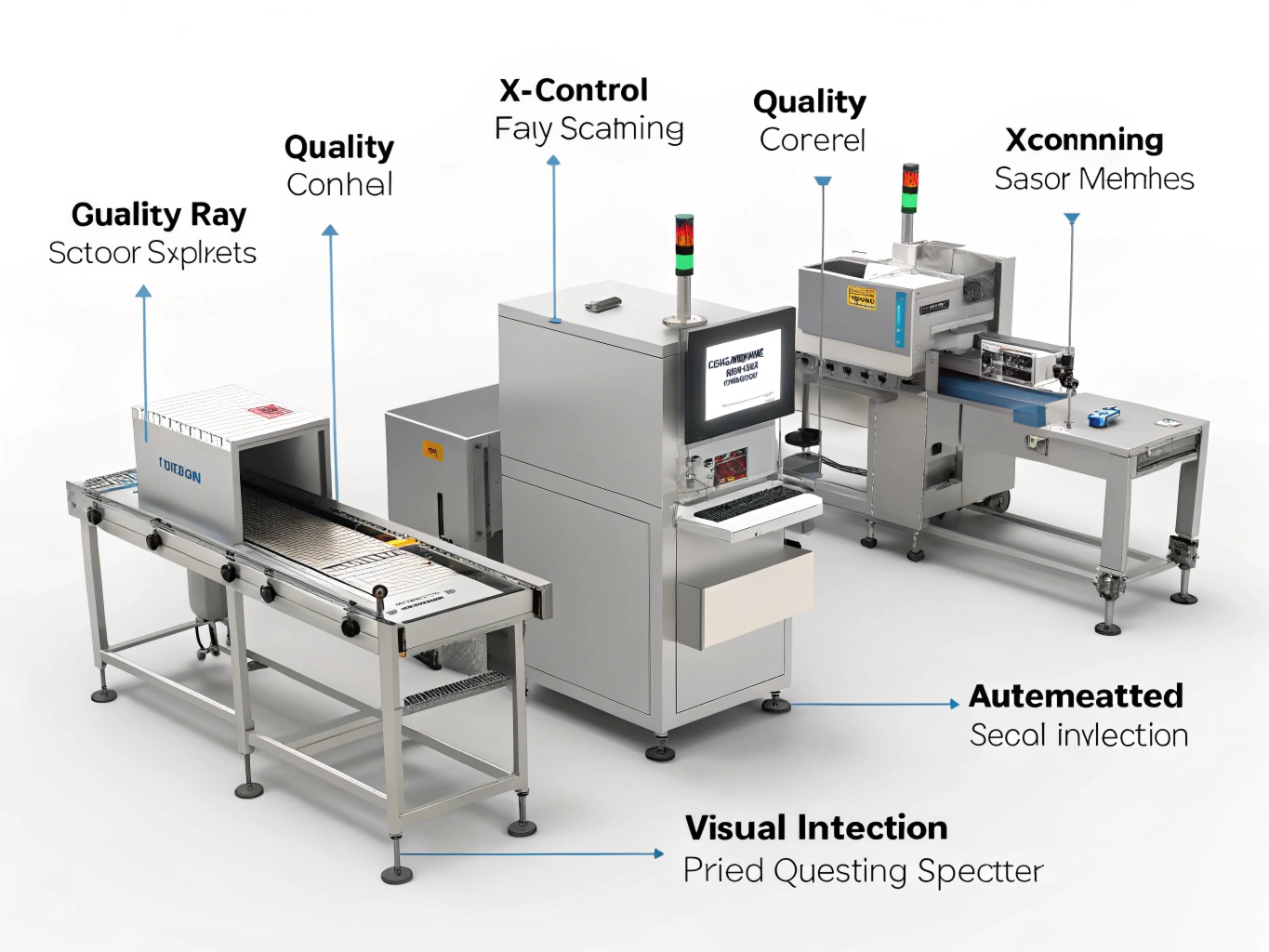

Visual inspection is a quality control method that uses either human vision or automated systems to detect surface defects, measure dimensions, and verify product quality. It can be performed manually by trained inspectors or automatically using machine vision systems.

Let me share my 20+ years of experience in manufacturing to help you understand how visual inspection works, what skills are needed, and how to choose between manual and automated solutions.

How To Do a Visual Inspection Properly?

Many manufacturers struggle with inconsistent inspection results1. A systematic approach to visual inspection2 can help maintain quality standards and reduce errors.

A proper visual inspection follows four key steps: preparation (cleaning and lighting setup), systematic examination of the entire surface, defect identification based on established criteria, and detailed documentation of findings.

When it comes to conducting visual inspections3 effectively, I’ve found that having a structured approach4 makes all the difference. From my experience working with various manufacturers, here are the key considerations:

Essential Components of Visual Inspection

-

Environmental Requirements:

- Lighting: 750-1000 lux minimum

- Viewing distance: 20-30 cm

- Viewing angle: 30-45 degrees

-

Inspection Sequence: Step Action Purpose 1 Surface preparation Remove dirt and contaminants 2 Systematic scanning Ensure complete coverage 3 Defect marking Document locations of issues 4 Measurement Quantify defect dimensions

What Skills Are Needed for Visual Inspection?

Poor inspection skills can lead to missed defects and quality issues. Proper training and specific abilities are crucial for reliable inspection results.

Visual inspectors need good eyesight, attention to detail, knowledge of quality standards, and specific certifications like ISO 9712. They must also understand material properties and common defect types.

The success of visual inspection5 heavily depends on the inspector’s capabilities. Based on our training programs and industry standards, here are the critical skills6 required:

Key Inspector Competencies

-

Technical Skills:

- Visual acuity (both near and far)

- Color discrimination

- Pattern recognition

- Measurement accuracy

-

Knowledge Requirements: Area Specific Knowledge Materials Properties and defect types Standards Industry specifications Tools Usage and calibration Documentation Report writing

When Should a Visual Inspection Be Done?

Timing inspection wrong can result in wasted resources or missed defects. Understanding the right moments for inspection is crucial for quality control.

Visual inspections should be performed at key production stages: incoming material verification, in-process quality checks, final product inspection, and during regular maintenance intervals.

From our manufacturing experience, the timing of visual inspection can make or break quality control efforts. Here’s what we’ve learned about optimal inspection timing:

Critical Inspection Points

-

Production Timeline: Stage Inspection Focus Pre-production Raw material quality During production Process control Post-production Final quality check Maintenance Equipment condition -

Special Circumstances:

- After machine setup changes

- Following customer complaints

- Before shipping high-value orders

How Much Does an Inspection Machine Cost?

Budget constraints often limit quality control options. Understanding inspection machine costs helps in making informed investment decisions.

Visual inspection machine prices range from $5,000 for basic systems to $500,000 for advanced automated solutions. Costs vary based on capabilities, precision requirements, and processing speed.

Having helped many clients select appropriate inspection equipment, I can break down the costs:

Cost Breakdown by System Type

-

Machine Categories: Type Price Range Features Basic $5K-$20K Simple defect detection Standard $20K-$100K Multiple inspection points Advanced $100K-$500K AI-powered, high speed -

Additional Costs:

- Installation: 10-15% of machine cost

- Training: $2,000-$5,000

- Annual maintenance: 5-10% of machine cost

Conclusion

Visual inspection success depends on choosing the right approach – manual or automated – based on your specific needs, implementing proper procedures, and investing in appropriate training or equipment.

-

Exploring solutions for inconsistent results can significantly boost your manufacturing quality and efficiency. ↩

-

Understanding this approach can enhance your inspection processes and improve quality control. ↩

-

Understanding best practices for visual inspections can enhance quality control and efficiency in manufacturing processes. ↩

-

Exploring the benefits of a structured approach can lead to more effective and reliable inspection outcomes. ↩

-

Exploring best practices can enhance your understanding of effective visual inspection techniques. ↩

-

Learning about these skills can help you improve your inspection capabilities and ensure quality. ↩

Written by

You may also be interested in:

What is the Best Optical Sorter?

You stare at dozens of optical

What is the vision system for visual inspection?

Modern manufacturing demands p